Entropy engineering for ultra-soft, highly tough silicone in 'burden-free' wearable electronics

GA, UNITED STATES, December 23, 2025 /EINPresswire.com/ -- An engineering team at Jiangxi Normal University, in collaboration with South China University of Technology, reports an entropy-driven strategy to construct low-topology-entropy silicone elastomers (LTE-SEs) in the journal Wearable Electronics. The materials achieve ultra-softness and ultra-high stretchability while maintaining high strength, and are successfully applied in skin-conformal flexible encapsulation, UV-protection patches, and fully encapsulated safety-positioning insoles, providing a new generation of substrate materials for long-term, comfortable, and reliable wearable electronics.

Wearable devices and smart textiles are rapidly evolving from “occasional use” toward “all-day, long-term” usage. However, many so-called flexible electronics have been described as “hard little plastic pieces hidden inside a bandage”, causing a strong foreign-body sensation on the skin and even degrading signal acquisition quality.

To address this, the SoftWear Engineering team led by Jianliang Gong at Jiangxi Normal University, together with Professor Lin Shu from South China University of Technology and Professor Yiwang Chen from Gannan Normal University, proposes a silicone elastomer design strategy based on network topology entropy engineering.

The researchers reported their results in Wearable Electronics.

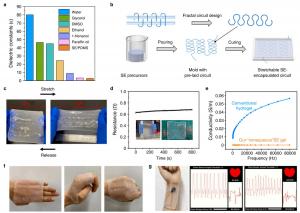

Building upon commercial addition-cured silicone systems, the team established a multi-step “swelling–crosslinking–replacement–deswelling” process, which rearranges the spatial distribution of crosslinking points without changing the chemical composition. They then constructed a low-topology-entropy network with a much narrower distribution of chain segment lengths.

The resulting LTE-SEs exhibited an initial modulus of only about 0.24 MPa, approximately eight times softer than conventional control samples, while their fracture strain reaches 1150% and toughness increases to about 24 MJ·m⁻³, thus unifying ultra-softness, ultra-stretchability, and high toughness in a single material system.

“In simple terms, we are using 'entropy' as an invisible hand to 'comb and straighten' the polymer network at the molecular level,” explains Gong. “The resulting silicone behaves as soft as jelly yet as robust as a safety belt, making it much more suitable for long-term wear on the skin.”

The researchers also demonstrated several representative on-skin wearable applications. “With LTE-SEs, rigid chips and interconnects can be encapsulated in a single-step 3D process to form ultra-soft, fully packaged devices that remain stable under large stretching, bending, and twisting,” shares Shu. “When a small amount of TiO₂ nanoparticles is incorporated into the matrix, the films can block 97.9% of incident UV light and, when integrated with audio-visual modules, function as all-in-one “UV sensing–shielding–alarm” skin patches.”

Notably, the fully encapsulated safety-positioning insoles maintain excellent mechanical integrity and electronic reliability even after 60 days of continuous wear in humid and sweat-rich environments, offering a practical solution for safety positioning and motion monitoring.

“We demonstrated that entropy-driven, low-topology-entropy silicone elastomers combine both comfort and durability, while remaining compatible with existing addition-cured silicone processing,” says Chen. “These features position LTE-SEs as a promising universal platform material for “burden-free” on-skin wearable electronics.”

Original Source URL

https://doi.org/10.1016/j.wees.2025.09.001

Funding information

This work was supported by the National Natural Science Foundation of China (Nos. 52463028 and 52103278), the Jiangxi Province High-Level and Urgently Needed Overseas Talents Program (No. 2021BCJ25001), and the Jiangxi High-Level Young Talents Innovation and Entrepreneurship Program (No. jxsq2023101108).

Lucy Wang

BioDesign Research

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.